Residual Stress Test

2018/9/29

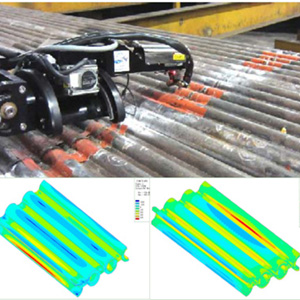

Metal materials produce different residual stresses during machining and hot working (casting, welding, forging). The existence of residual stress, on the one hand, the workpiece will reduce the strength, causing deformation and cracking of the workpiece during manufacturing; on the other hand, the mechanical properties such as fatigue strength and stress corrosion of the material will be reduced during the natural release process after manufacture. . This causes problems in use. Therefore, the detection of residual stress is very important for the heat treatment process, the surface strengthening treatment process, the effect of the stress relief process and the waste analysis.

|

|

Shanghai Rays Testing Co.,Ltd. All rights reserved ICP:18015072 Disclaimer